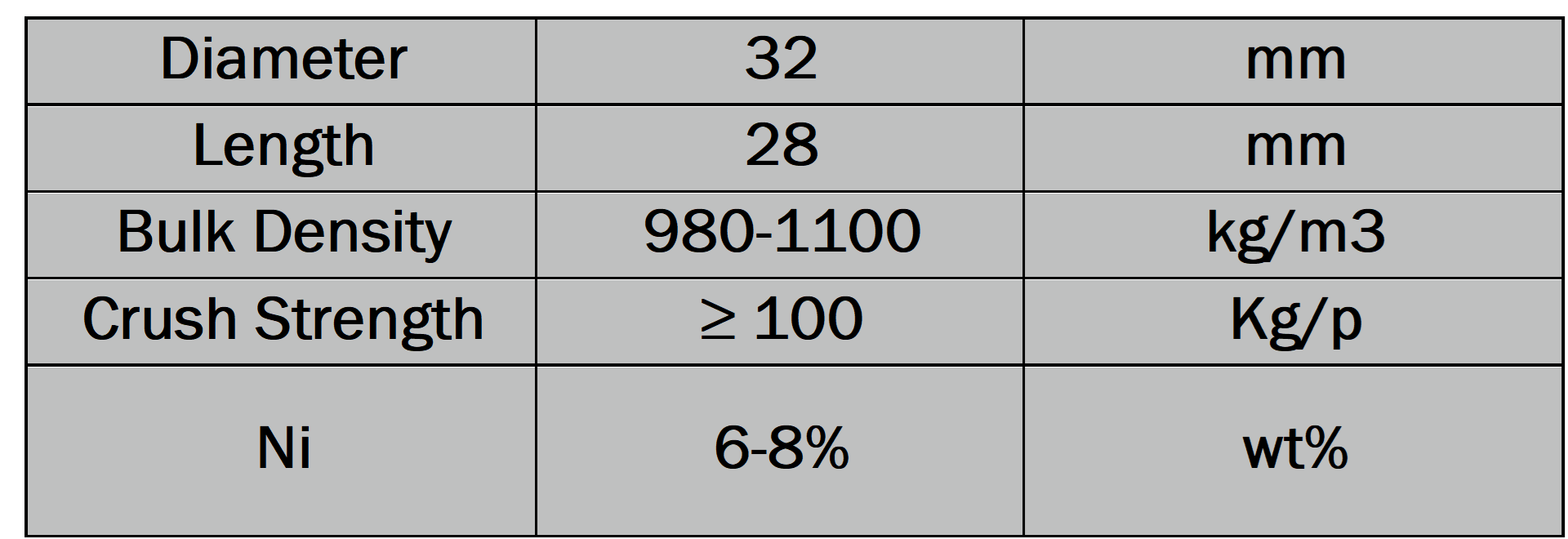

RT-DR-28

Nickel-Based DRI-Reforming Catalyst

DRI process, high-activity catalyst

RT-DR-28 is a newly developed nickel catalyst on a calcium aluminate support, which has been optimized for shape. It is specifically tailored for use in the Midrex DRI process, but can also be used in H2 production units that utilize natural gas and Coke Oven Gas (COG). Our unique sphere shape for maximum pressure drop and high flow through the tube. Very high compressive strength between 30-50% higher than other catalysts.

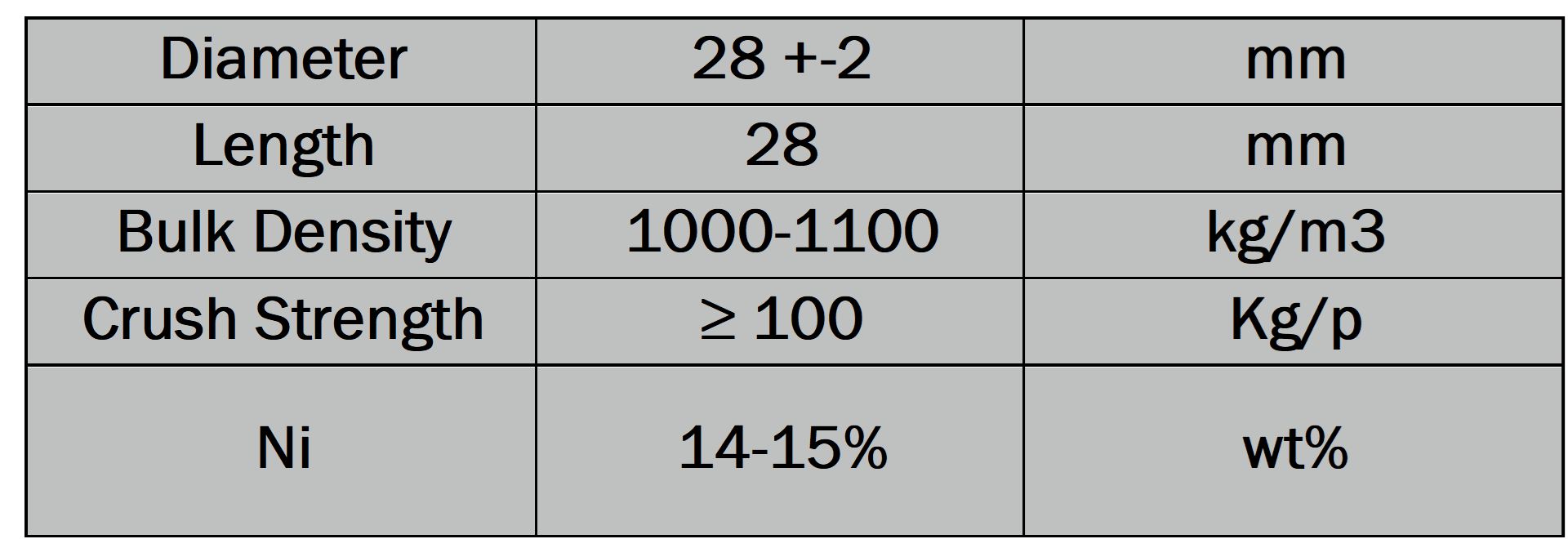

RT-DR-26

Nickel-Based DRI-Reforming Catalyst

DRI process, medium activity catalyst

RT-DR-26 is a newly developed nickel catalyst on a calcium aluminate support, which has been optimized for shape. It is specifically tailored for use in the Midrex DRI process, but can also be used in H2 production units that utilize natural gas and Coke Oven Gas (COG). Our unique ring shape for maximum pressure drop and high flow through the tube. Very high compressive strength between 30-50% higher than other catalysts.

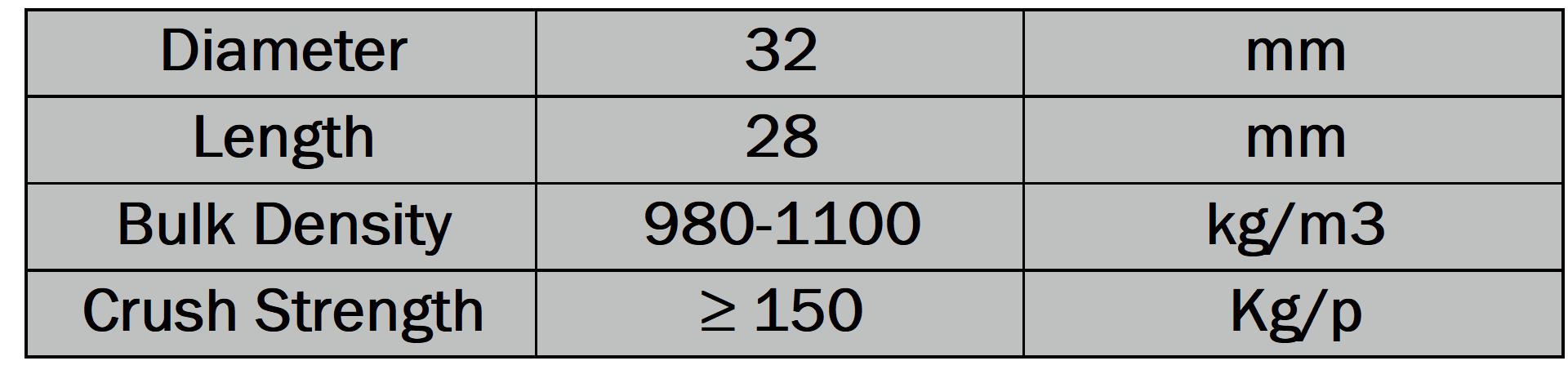

RT-DR-24

DRI Pre-Reforming Catalyst

Inert for Midrex Reforming

RT-DR-24 is an inert support that is custom-made for the Midrex DRI process. It is also suitable for H2 production units that use natural gas and Coke Oven Gas (COG). Our unique ring shape for maximum pressure drop and high flow through the tube. Very high compressive strength between 30-50% higher than other catalysts.