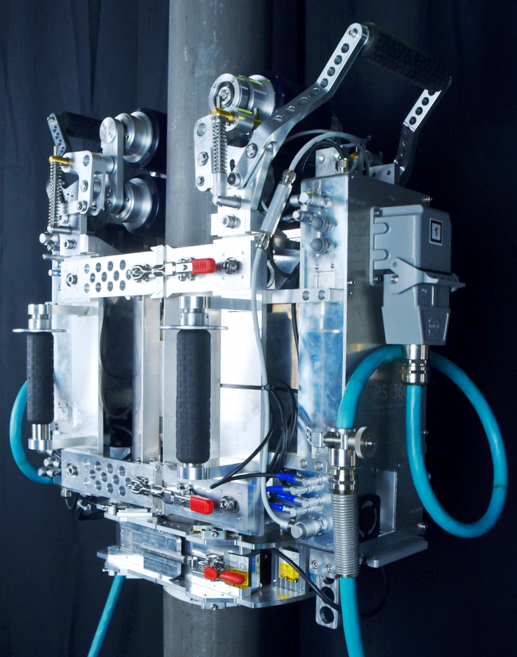

Reformer Pipe Scanner (RPS)

The Reformer Pipe Scanner OD is equipped with a powerful proprietary eddy current probe for sensitive crack detection in reformer tubes up to 23mm wall thickness. As this proprietary technique needs no couplant, the readings are repeatable from one inspection to the next inspection. Both measurements expansion and crack detection are carried out simultaneously during the inspection over the entire length of the tubes OD surface. During each tube inspection, millions of data points are collected on each tube. With this data, we will provide a report to the customer before leaving the plant. We are also able to provide the customer with a Level 1 FFS or Level 3 FFS report with this data.

Key Benefits:

• 6-point laser inspection over entire length of inspected tube

• Collects millions of data points during each tube inspection

• All recorded data can be used in Reformer Tube Assessment 360

• Repeatable, accurate and fast inspection

• Eddy Current crack detection of each reformer tube

• Manufacturing flaws • Early warning of problems before tube failure

• Provides baseline measurements for new tubes

• Identifies failure mechanisms in individual tubes:

• Creep strain

• Bulging

Result Documentation

EC Testing

• Eddy current result presentation in color scan mode for the entire tube

• Easy identification of defects

Laser Testing

• Evaluation of min., max. and mean diameter for each tube section at the whole circumference (internal reformer tube testing)

• Evaluation of min., max. and mean diameter for each tube section at 3 circumferential positions (external reformer tube testing)

• Comparison of max. diameter to nominal and/or mean diameter for each tube section

• Comparison of data with previous or fingerprint laser testing data (optional)

Remaining Life Assessment (RLA-360)

Remaining Life Assessment of Catalytic Reformer tubes is a complicated task that requires taking into account several different damage mechanisms.

With our proprietary RLA-360 program we’re able to predict remaining tube life in accordance with API 579-1/ASME FFS-1 standard. The program uses data collected from the inspection, both expansion and cracking along with operational data from the plant to help accurately determine the remaining life of each inspected tube.